Modern CNC-controlled machine systems as well as a production and storage area of more than 5000 square meters

With modern production facilities, we can produce the desired solutions for you. We work efficiently, reliably, precisely and cost-effectively. Our many years of experience in processing elastomers and other cellular materials is a guarantee that we can meet your high standards. We want to INSPIRE you in terms of quality and service!split

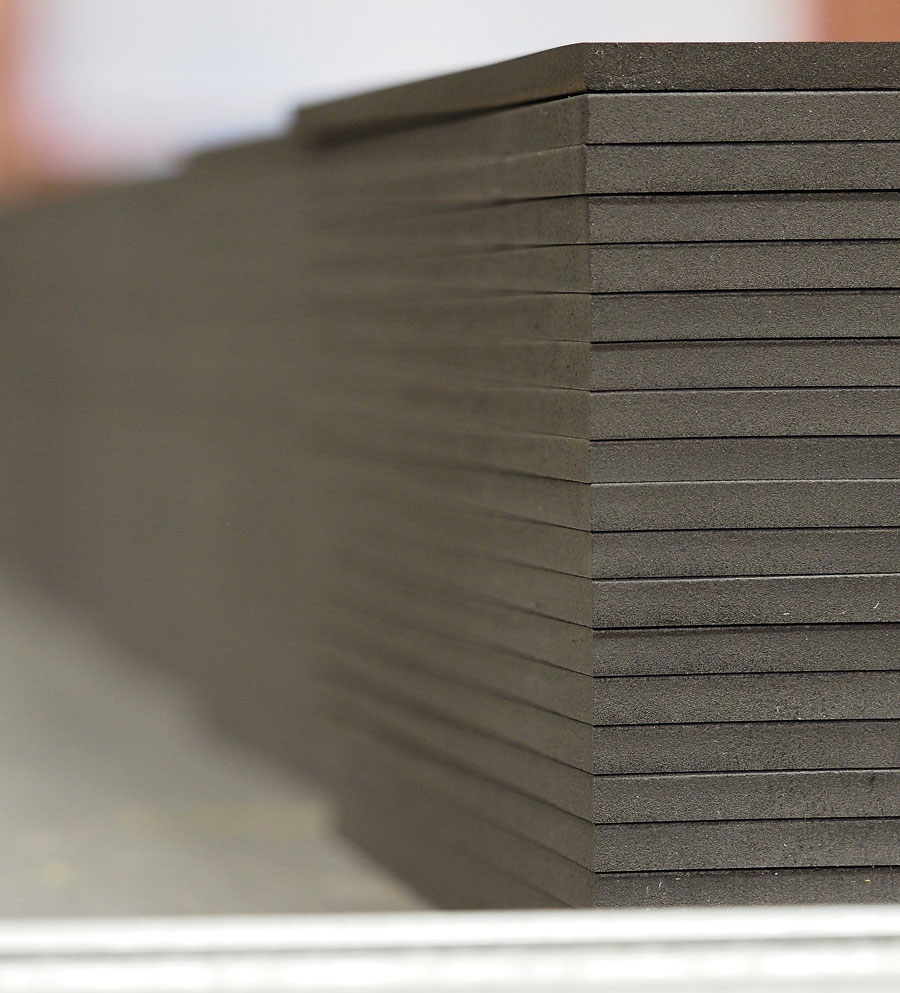

Splitting machines are required to produce millimeter-thick sheets (e.g. 3 mm) from the raw blocks (approx. 2000 x 1000 x 1000 mm). We either process these plates further or send them to our satisfied customers.

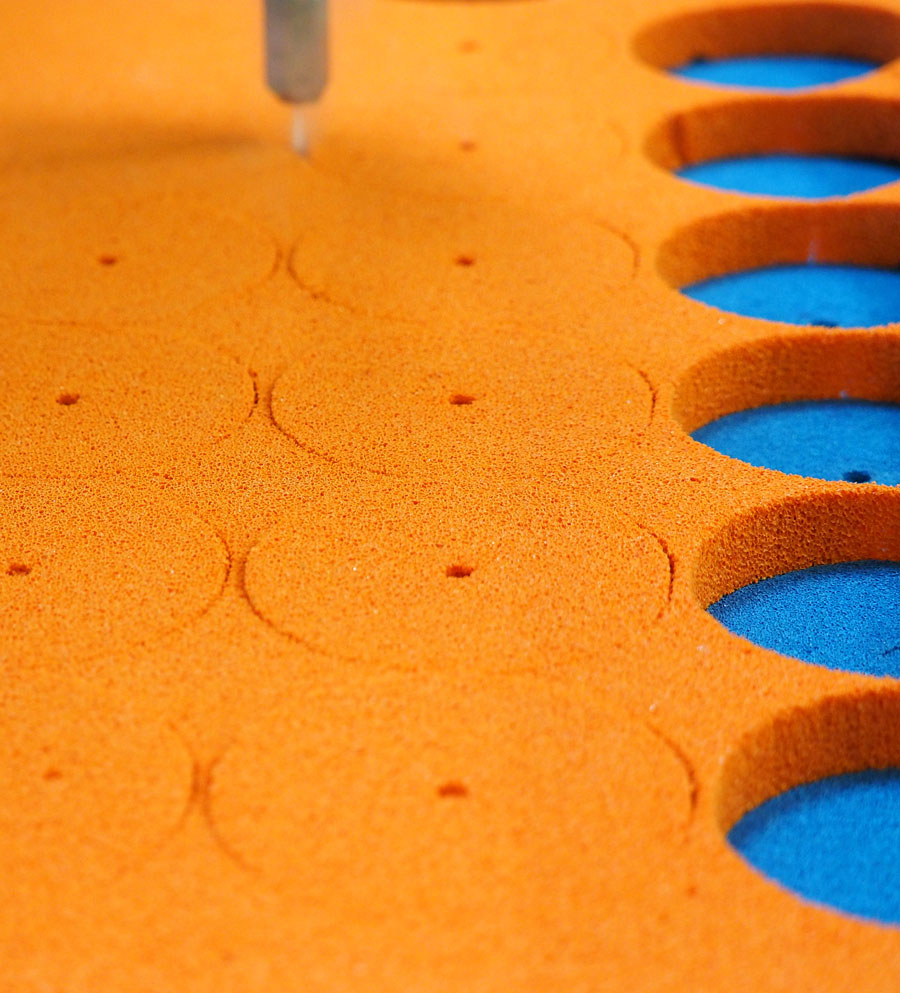

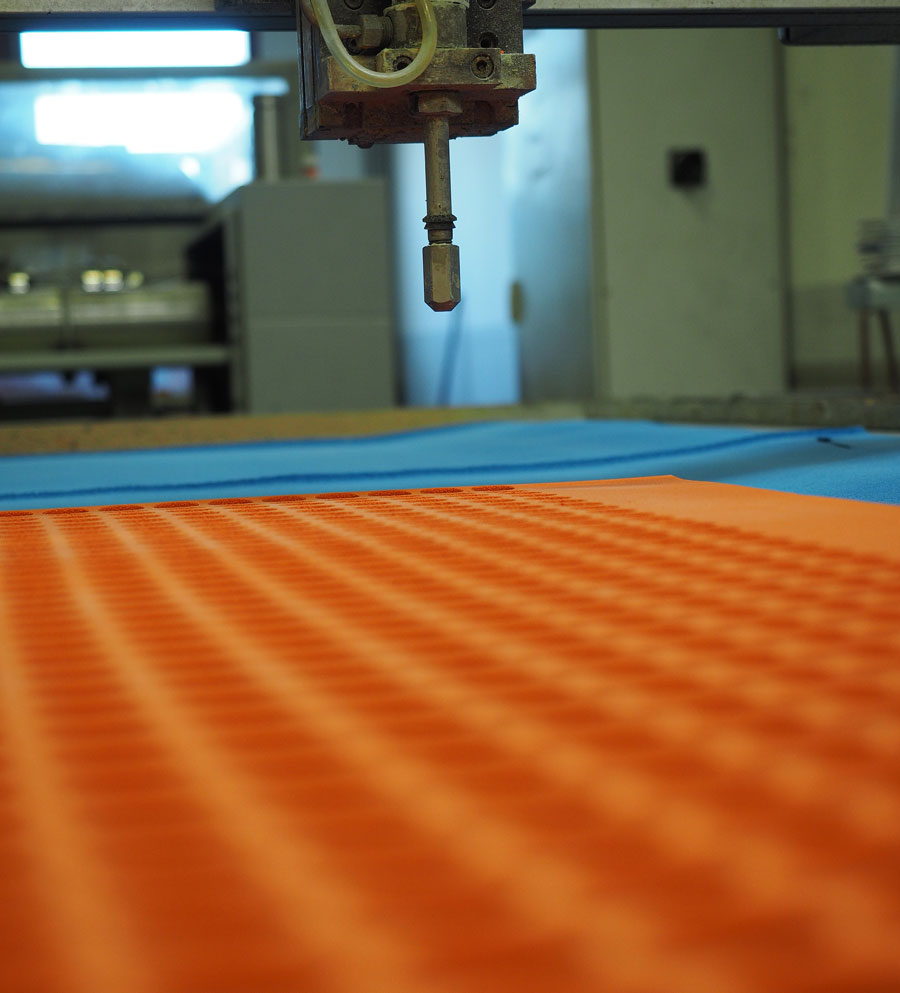

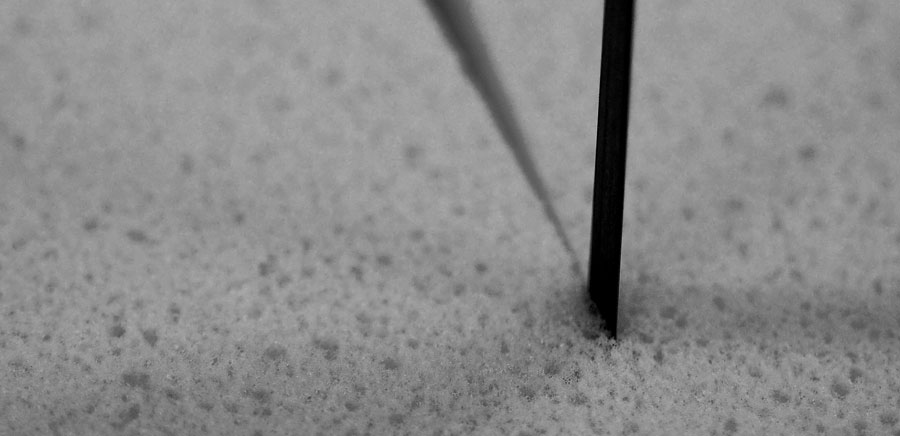

water jets

A decisive advantage of water jet cutting is the high flexibility and variability. The cutting process does not require any tools and is particularly suitable for precise individual parts and series.

Either you provide us with your CAD data or we create a corresponding CAD drawing for you. With the help of innovative water jet technology, all of our raw materials can be processed quickly and precisely.

punch

For large contours made of foam, sponge rubber or cellular rubber, punching is still the most economically interesting form of assembly. The larger the purchase quantity, the greater the savings potential compared to more modern assembly methods, such as water jetting. For example, we punch you also a float for your smoothing tool.

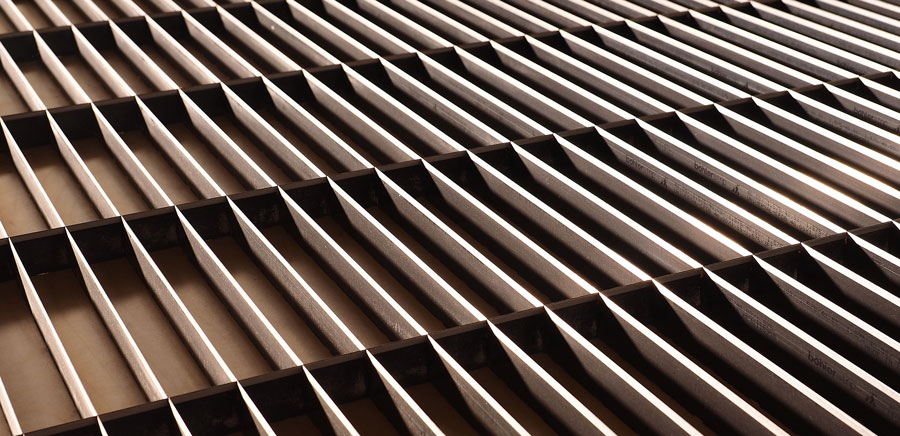

cutting

If the contour is rectangular and easy to machine, then our CNC-controlled cutting machines are used. Here, too, you are able to cut in multiple layers and thus produce inexpensively. For example, cuts for window wipers are cut here, or coverings for joint boards made of various materials.